Stainless Steel Wool

Stainless steel wool is specially suited for many muffler / exhaust manufacturers, industrial insulation, thermal insulation in power stations, gas and liquid filtration, pipe insulation, mist eliminators, heavy metal separation when corrosive, rust, tinder and heat are a concern.

Product characteristics of Stainless steel wool:

- Continuous ribbon of Stainless steel wool, Type AISI 434 (316L -special order)

- Three common grades: Fine(50 micron), Medium (80 micron), Coarse (120 micron)

- Density is controlled and specified in grams per linear meter

- Excellent media source for corrosion resistance, noise reduction, and heat insulation

- Heat Resistance up to to 800° C

- Typical Reel size is 4″ wide and ¼” thick ribbon in 5 lb or 10 lb rolls (other sizes available)

- 5lb roll consists of approximately 125′ linear feet of continuous steel wool ribbon

- Highly Resistant to Exhaust Acids and High Vibration, Making it an Excellent Material for Muffler Baffling.

Type 434 Typical Chemistry:

C 0.12% max. ; Si 1.0% max. ; Mn 1.0% max. ; S 0.03% max. ;P 0.04% max.;

Cr 16.0 – 18.0% max. ; Mo 1.25% max.; Fe-balance.

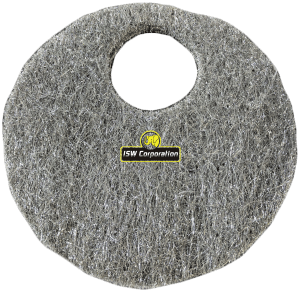

TEXSTEEL Stainless Steel Wool:

- Consists of multiple cross layers of stainless steel wool with mechanical bonding.

- Provides added strength and most consistent density for exhaust applications.

- Bulk roll widths up to 75″ wide or die cut to specific sizes.

- Thickness from ¼” up to 1″

Custom Tubes and Die Cuts:

- Stainless steel wool tubes or die cuts made to your exact specifications for pipe length or diameter for fast installation over baffles or inside muffler canisters.

- Multiple tube assembly and combinations of basalt or fiberglass wool depending on your specifications.

- Beneficial to reduce labor and installation costs.